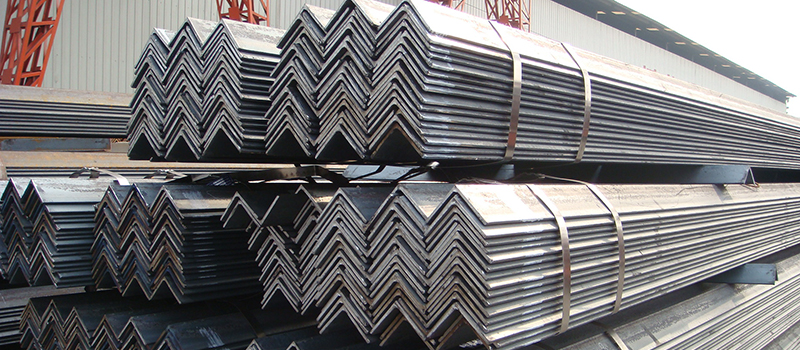

MS Angle Manufacturers

Looking for MS Angle Manufacturers in Australia? Your search ends here! Businessetu lists a number of leading MS Angle Manufacturers from India and connects you with India's leading manufacturers and exporters known for their exceptional quality and competitive prices. India's improved trade policy and close relationship with Australia make exporting a breeze. Whether you need a custom or standard-size MS Angle, our marketplace offers comprehensive options for MS Angle traders. Discover the benefits of sourcing from India and get in touch with reliable manufacturers today to get high-quality MS Angles at unbeatable prices.

Product Specification of MS Angle

| Specification | Details |

|---|---|

| Type | Equal Angle, Unequal Angle |

| Material | Mild Steel (MS) |

| Standard | IS 2062, IS 808, ASTM A36, EN 10025 |

| Dimensions | Varies; Common sizes range from 25mm x 25mm to 200mm x 200mm |

| Thickness | Typically ranges from 3mm to 25mm |

| Length | Standard lengths: 6 meters, 12 meters |

| Surface Finish | Hot Rolled, Galvanized, Painted, Black |

| Tensile Strength | Typically around 410-430 MPa |

| Yield Strength | Typically around 250-260 MPa |

| Elongation | Minimum 20% |

| Applications | Construction, Infrastructure, Industrial, Fabrication, Machinery |

| Corrosion Resistance | Galvanized and painted options available |

| Weldability | Good, suitable for welding |

| Machinability | Good, easy to cut, drill, and machine |

| Tolerance | As per IS 1852, IS 808 |

| Certification | BIS Certified, ISO Certified |